Defective CNC machine by Merchant Dice Ltd (MDL)

This article is a user review of the purchase and assembly of a defective CNC machine by Merchant Dice Ltd (MDL) before new year 2011.

UPDATE: From 2011 to 2016 allot of people have corresponded with me to report similar defects. So it seems after 5 years Merchant Dice has little interest in creating a quality product. Potential customer, learn from our mistakes. Stay away and buy elsewhere, even from Germany, as quality on average is allot better and shipping costs can be competitive if you discuss it with them.

CNC Background

CNC machine prices have fallen dramatically over the last 20 years and with the wide variation and ready supply of off-the-self parts, CNC machining is now more cost effective and accessible to everyone. But within this lies the problem, “How can you judge the build quality of a CNC machine before you make the purchase”?

Well by reviewing onc such CNC machine produced by MerchantDice.com, I hope to fill in some of the pros and cons for you, so when it comes your turn to make this large purchase, you will have the foresight of others to make better and wiser choices.

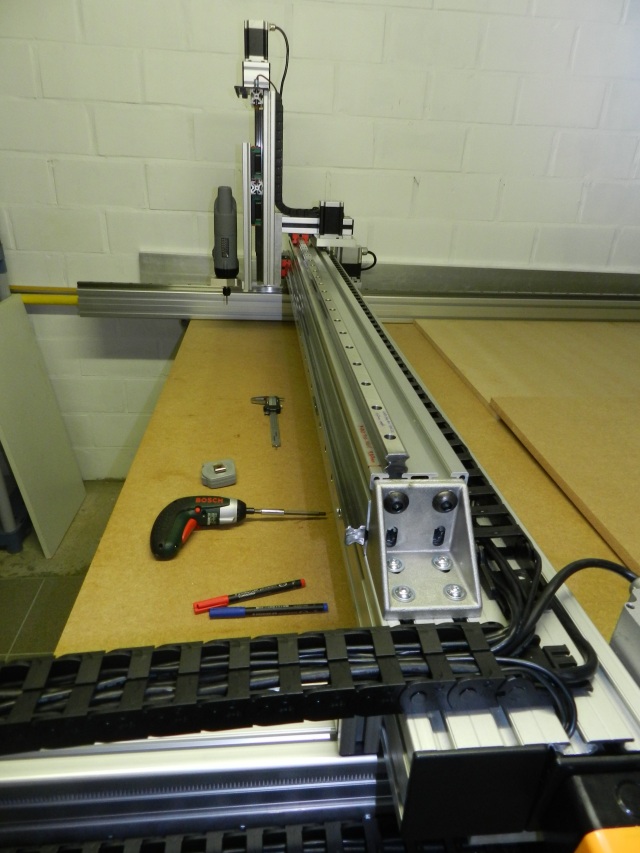

MerchantDice 2900 x 1680mm CNC Router

The CNC machine under review here is a cost effective self assembly 3-axis machine made from Aluminium profiles that lies between the semi-professional and professional CNC machine.

First, not all CNC machines are the same, and the higher the price you pay does not always reflect higher quality. Many have pitfall like accuracy, build quality, usability, high initial cost and/or poor scalability – hard to adopt the machine as your requirements change – like the addition of a extra axis or machining different materials. MDL’s CNC machine was chosen to overcome most of these hurdles. Now lets see is this the case.

| Dimensions | |

| Outer area (LxWxH) | Advertised: 3100 x 1800 x 810 mm Shipped: 2900 x 1660 x 774 mm (dimensions excludes table stand) |

| Working area (L x W x H) (X x Y x Z) |

Advertised: 2500 x 1250 x 175 mm Shipped: 2500 x 1250 x 175 mm |

| Acclaimed Travel | Repeatability: 0.010mm Accuracy: 0.020mm Resolution: 0.010mm |

| ..more to come… |

NOTE: with reference to the CNC terminology, our tabular axis is the X-axis (MDL Y-axis) and our bridge axis is the Y-axis (MDL X-axis).

The CNC machines Y and Z axis came pre-assembled. The remaining installation tasks were performed as follows

- placed and secured the X-axis Aluminium profile on its worktable,

- saddle the Y-axis Aluminium profile linear guides onto their supporting X-axis Aluminium profile linear rails.

- saddle the Z-axis units linear guides onto their supporting Y-axis aluminium profile linear rails.

- attach the motor, signal, and spindle cables along the x-axis and y-axis raceways.

- attach the motor, signal and spindle cables to their CNC Controller ports.

- attach the CNC controller to the PC and install Mach 3 CNC software.

- startup the CNC controller, and test the Emergency-Stop button, followed by the NEMA step motor motion on the Y and Z axis, including stop signaling.

- test and attach the two remaining NEMA 34 step motors with its X-axis rack and pinion mounting brackets.

- restart the CNC controller, and test the Emergency-Stop button again, followed by the NEMA step motor motion on the X, Y and Z axis including stop signaling on all axis.

Defects found

On assembly on the CNC machine, multiple defects in parts, workmanship and quality were found, most being critical. The defects were so prominent, that the machine acclaimed travel accuracy and repeatability postulated above is just a pipe dream.

I requested MDL to work with me to resolve these defect over the next few week. Progress report will follow.

X-Axis

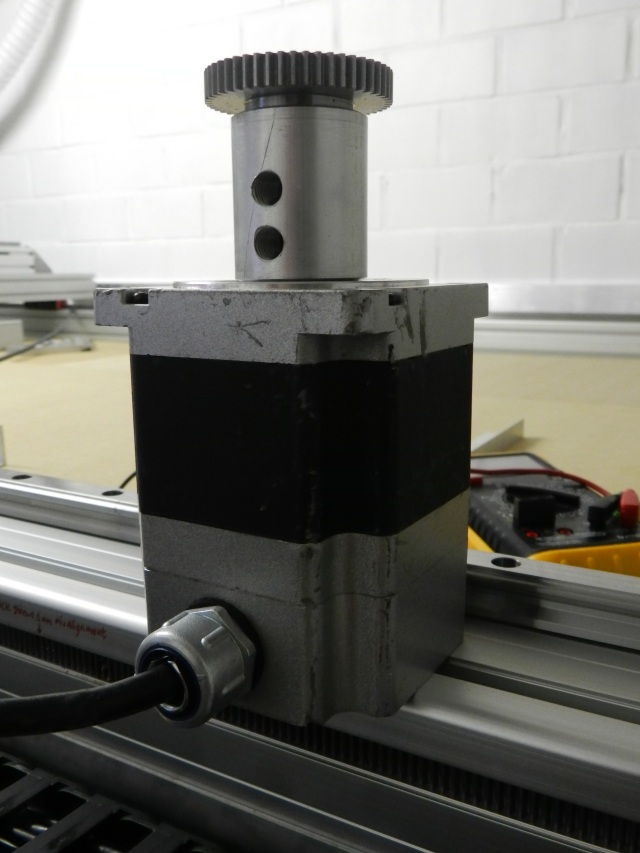

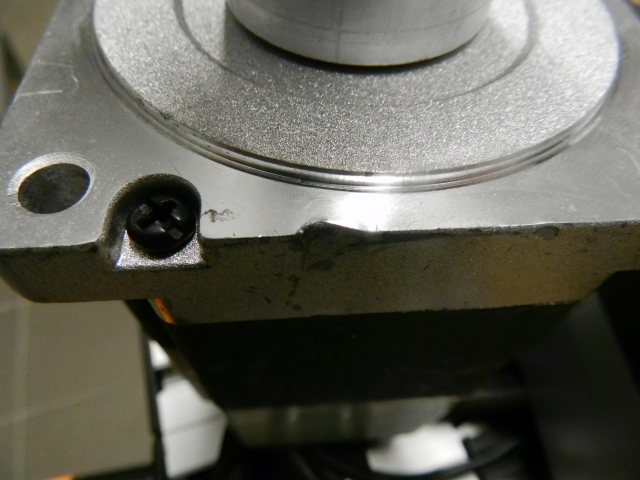

Defect 1) X-Axis NEMA 34 motor 1 is damaged and has non-concentric coupler and pinion gear rotation

Rack and Pinion – MerchantDice custom coupler and pinion gear are misaligned to the NEMA 34 step motor. The pinion gear concentric rotation it way out of line by 1mm+ both horizontal and vertical. Therefore when an attempt was made to run the motor along the X-axis, the pinions non-concentric rotation caused noise on the rack. After a short travel, the pinion was taken of the rack immediately to prevent any further damage to the rack and pinion. The stepper motor also noised under low torque.

Stepper Motor – The NEMA 34 Stepper motor outer casing is damaged, which can only be the result of miss treatment and falls, making the motor defective. The dents to motor casing indicate it has been dropped more then once – done 12 rounds with Mike Tyson. A basic quality control process before shipment would have highlighted these defects.

Dropping or hitting the motor equates to throwing the motor away. It will be unbalanced and will have lost part of its magnetism. Yes it will most likely still work but will not be as strong in torque, or as even in movement steps (both of the things you use a stepper for and both that can cause a lot of lost time trying to find and elusive fault).

A further ramification is that the stepper motor is also out of line with its sister NEMA 34 motor on the opposite side of the X-axis, which will cause accumulative damage to the sister motor and HIWIN liner guides on the X-axis over time; as the linear travel torque will be out of line leading to defective routing.

The following 2 videos highlight the NEMA 34 motors defect showing the non-concentric coupler and pinion gear rotation.

The following photos highlight some of the damage to the motors outer casing. Did not have time to take photo of all fours side.

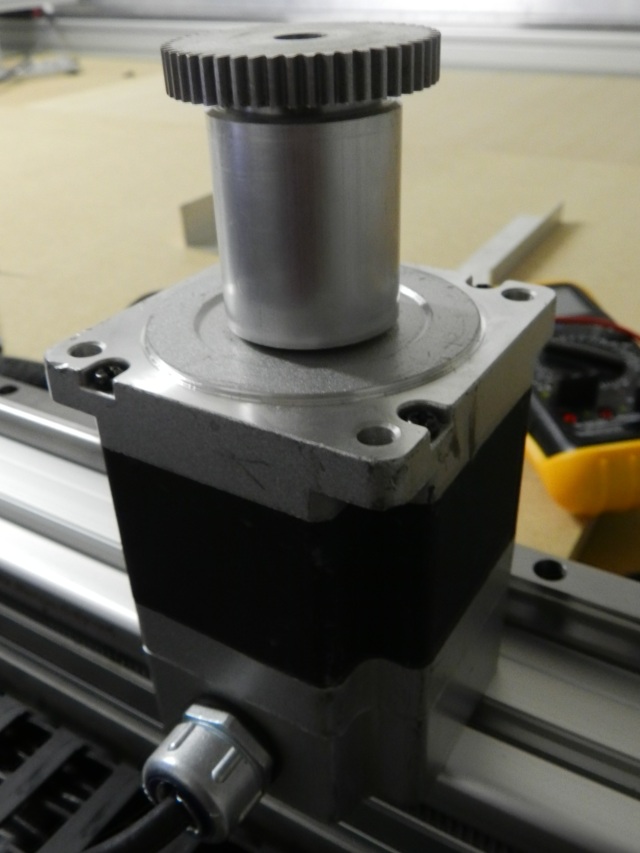

Defect 2) X-Axis NEMA 34 motor 2 has slight non-concentric pinion gear rotation

Here we examine the second MerchantDice X-axis NEMA 34 step motor.

UPDATE: 17/01/2012

On removal of the motor last weekend from its aluminium mounting plate (see photo below), it to was found to be damaged prior to final assembly and shipment. The damage again looks to be the result of miss treatment/falls, making the motor defective. To repeat: Dropping or hitting the step motor equates to throwing the motor away. It will be unbalanced and will have lost part of its magnetism.

The coupler and pinion gear of the second X-axis NEMA 34 step motor is less misaligned then the first motor, but maybe within tolerance – further testing will tell! Unlike its sister motor, no motor noise under low load (torque) was notable. But this may change when tested under higher real world loads. This will have to be delayed until the defects are ironed out by Merchant Dice.

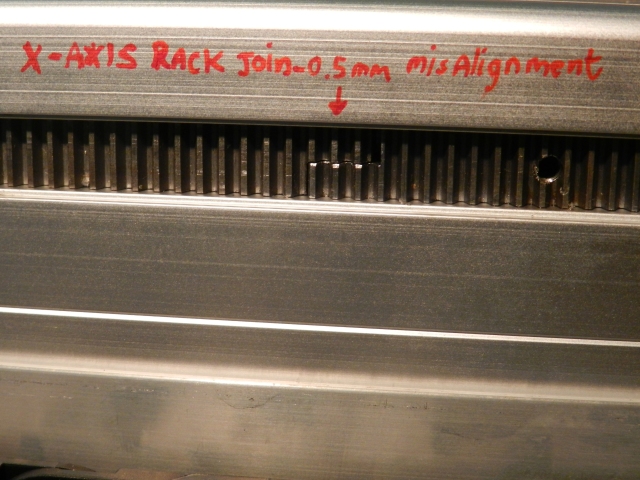

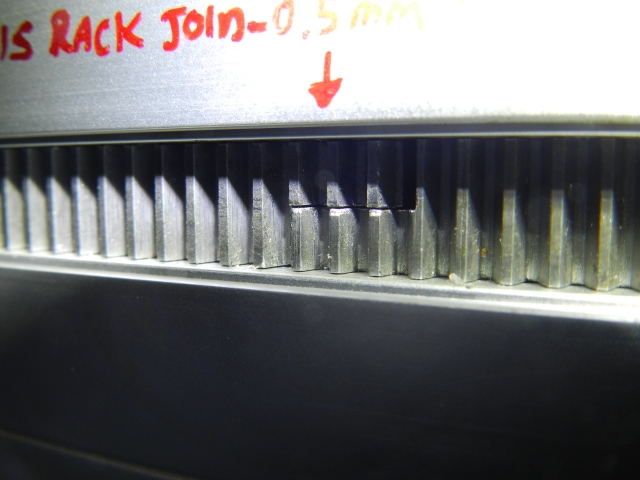

Defect 3) Rack out of line by 0.5mm

As you did not have a 2900 mm rack, the rack on the X-axis is made up of 2 racks joined end to end. This is understandable. But i noted the second rack is joined end-to-end with the first using an L-join, which is miss aligned by 0.5mm,. This causes accumulated error over the full travel length. The L-joint also reduces the rack surface available to the pinion gear thereby also introducing additional error.

The two rack should have been simply joined end-to-end and aligned using a “companion” rack, which meshes between the two rack sections, thereby minimising end-to-end error.

Additionally, the 2 fixing bolt holes in each rack (one on the right in the picture below) are also excessively big leaving little rack tooth available for the pinion to travel/grip on, thereby introducing the opportunity for more accumulated error.

Y-Axis

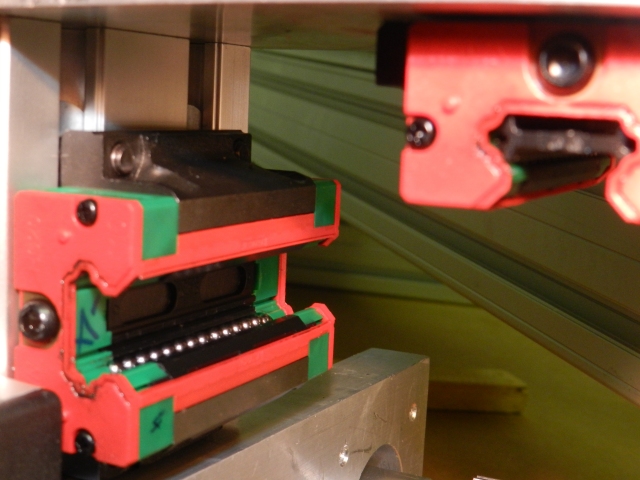

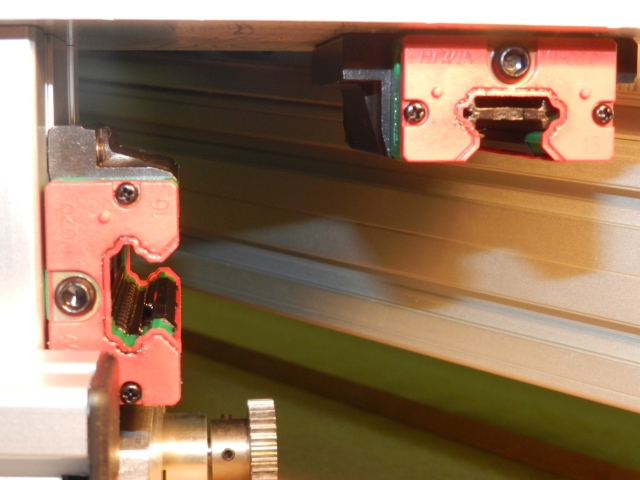

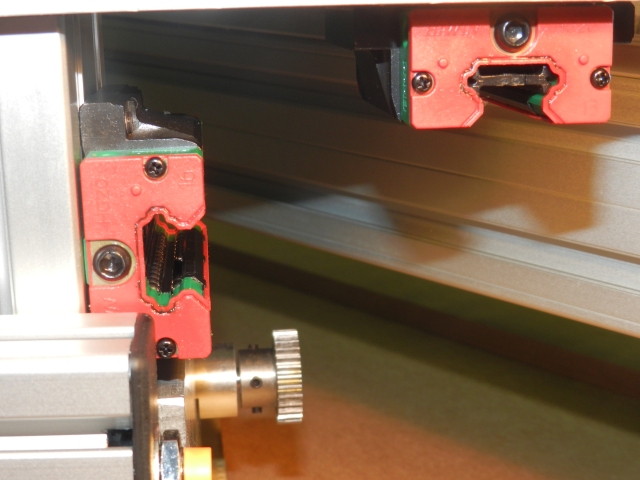

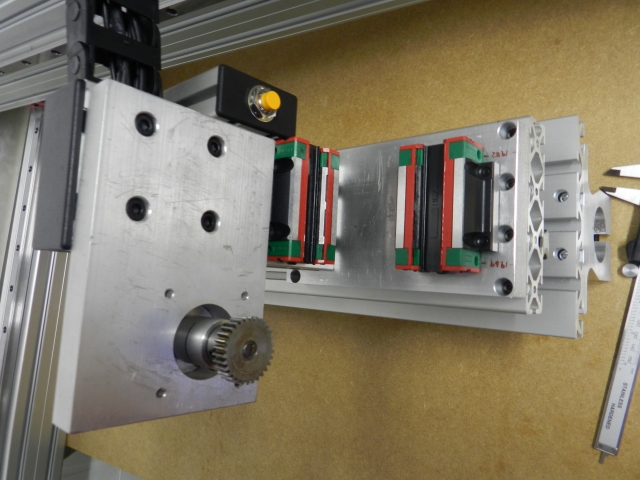

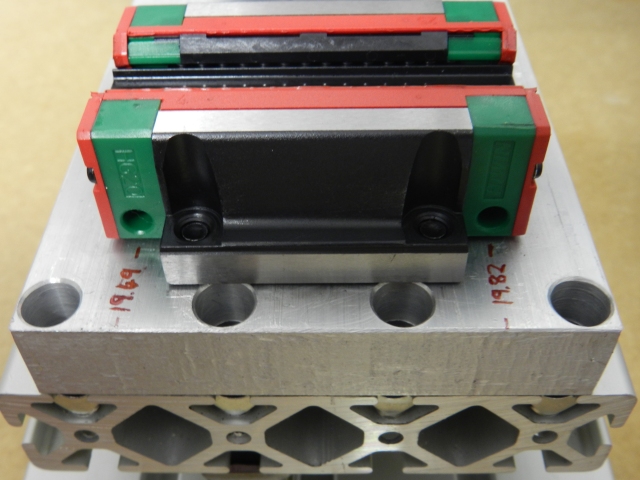

Defect 4) HIMAC linear guide carriage

The Y-axis has two HIWIN linear guide (HG20) and rails (HGR20C). Each liner guide has 4 recirculating baring carriages. 4 roller baring are missing from one of the HIWIN linear guide carriages. This was known before you assembled the part as -4 was marked on the inside of the carriage housing. Off the 3 photos below, the last 2 highlight the missing bearing on the bottom left of the image.

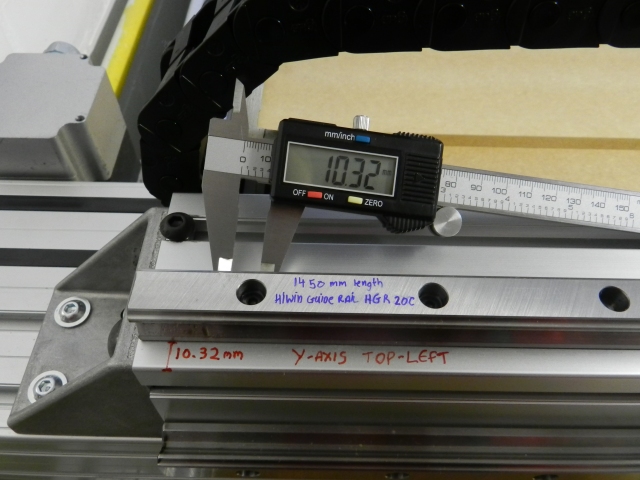

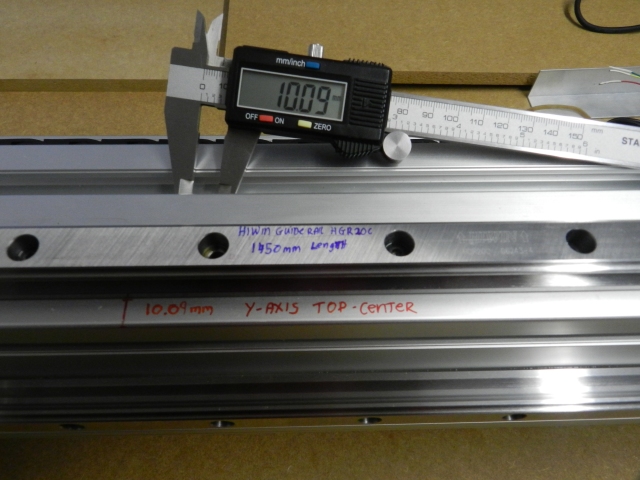

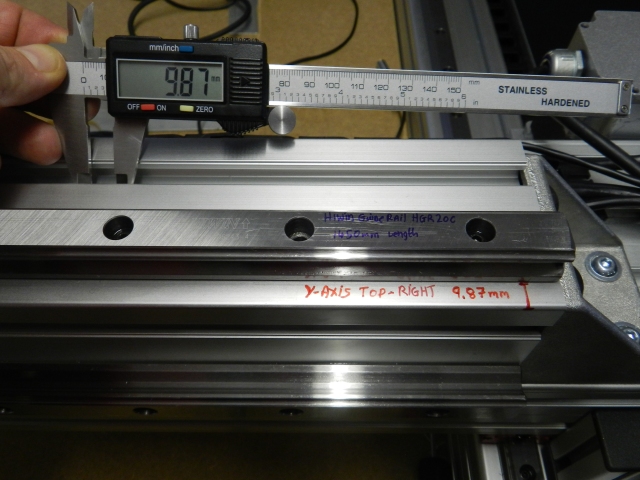

Defect 5) Misaligned Y-axis linear rail

The Y-axis has two HIWIN linear rails (HGR20C). The top HIMAC rail is misaligned on the aluminium profile and is out my approximately 0.45 mm from end to end.

Defect 6) Misaligned Y-axis linear guide

The Y-axis has two HIWIN linear guides (HG20). The bottom guide is misaligned on its aluminium rest plate and is out my approximately 0.33 mm from end to end.

Z-axis

Looks good. No issues found.

CNC machine as a whole

Defect 7) Missing Cover caps for linear rail fixing holes

All the HIWIN HGR20C rails on the X, Y and Z axis are missing their cover caps that come free with the rail. 152 cover caps are missing in total. The cover caps are used to keep the fixing holes free from chips and dirt, and thereby avoid damage to the HIWIN linear guide block dust protection end-seals and thereby to prevent shortening of the guide service life due to damage to the block caused by the penetration of metal chips or dust.

Thats why cover caps are supplied with each rail at no extra cost, so there is no excuse why they are missing.

8) Missing Aluminium profile PVC cover strips

As reflected in the CNC product photo, the Black PVC Cover Strip covers all exposed aluminium profile slots. The profiles support the X, Y and Z axis.

Yet my shipment contained cover strips for

- 0% of the X-axis aluminium profile,

- ±10% of the Y-axis aluminium profiles and

- ±15% of the Z-axis aluminium profiles.

Missing 5.7 meters of Black PVC Cover Strip for 6mm T-Slot profile (Hepco 1-242-1016)

– Z-profiles: (0.27m x 4) + (0.45m x 5) + (0.21 x 1) + (0.06 x 24)

= Total: 5.7 meters

Missing 69.42 meters of Black PVC Cover Strip for 10mm T-Slot profile (Hepco 1-242-1037)

– X-Profiles: (2.9m x 14) = 40.6m

– Y-Profiles: (1.8m x 12) + (1.45m x 4) + (0.18 x 4) = 28.12m

– Z-Profiles: (0.35 x 2) = 0.7m

= Total: 69.42 meters

9) CNC Machine footprint and Working area

Footprint

- Length is 2900, not 3100mm as advertised, which indicates the X-axis aluminium profile was cut shorter then the advertised length.

- Width is 1660, not 1800 as advertised, which indicates the Y-axis aluminium profile was cut shorter then the advertised length.

Working area:

- As advertised.

What was the outcome. Have Merchant Dice fixed the defects in the CNC machine you purchased?

James, Oxford UK.

Yes, CNC machine after 4 months of waiting did resolve most issues outlined. They replaced all defect parts with new parts and covered the cost of shipping. But quality is still questionable. My advise is to buy elsewhere, even from Germany as shipping costs are feasible.

Hello

I am planning to build a merchant dice machine. I would like to talk with you about your experience but I cannot find your email. Can you contact me to the supplied email ?

Thanks,

Kevin Donnot

Hi Kevin. I replied to your email (although rather late).

Pingback: Looking to buy a ~4'x4' CNC router, advice welcomed

They are not the only one . I imported an USA made small machine to Europe and had to fix similar problems. Grrrr, things that you could expect from China .

Hi,

Thanks for the review, it was so informative. I have just built my first machine out of plywood and I am currently in the experimental phase. Cutting the wood by hand in my loft has resulted a loss in accuracy, so this machine is all about getting use to software ect. I have been looking at the Marchant Dice machine for a while now in an attempt to replicate the design. I have five kids, so buying a machine is out of the question.

I wonder if you could help answer a couple of questions that I have not been able to get to the bottom of?

1) what are the dimensions of the Hepco Aluminum Profile. I am assuming that the upper sections are 80 x 80mm, with the bottom support section being 40 x 80mm. ( I Have the dimensions for the Z axis).

2) I have looked at the dimensions of the channels in the 80 x 80mm aluminum profile, and can not see how the pinion racks that Marchant Dice supply will fit in the channel, can you give me the dimension of the rack supplied? and if not to much trouble a photograph in section view.

3) I am assuming that the Hiwin rails are fixed using the T slot fixings from Hepco. Can you confirm this? Again a photograp would be much appreciated.

Thanks in anticipation to your reply

Gary Collum

Bought cnc from them and could not recommend them, slow response, zero aftermarket support, rude and unhelpful. unfulfilled promises – I regret buying

Pity to hear that Borgyz. Seems after 5 years Merchant Dice has no interest in creating a quality product or providing proper customer support.

Potential customer, learn from our mistakes. Stay away and buy elsewhere, even from Germany, as quality on average is allot better and shipping costs are feasible.